LSZH and PVC jackets are just two common terms that we often use when referring to communication cables. These words are the description of chemical mixtures used when it comes to producing cable networks.

These terms may be so familiar, however do we really know what they mean? Also, it is important to know which of these two cables are ideal for your project or specific needs. Hence, this article will give you an idea what LSZH and PVC jackets are and their comparison.

If you are ready, let’s get started.

LSZH and PVC Jackets — What are they?

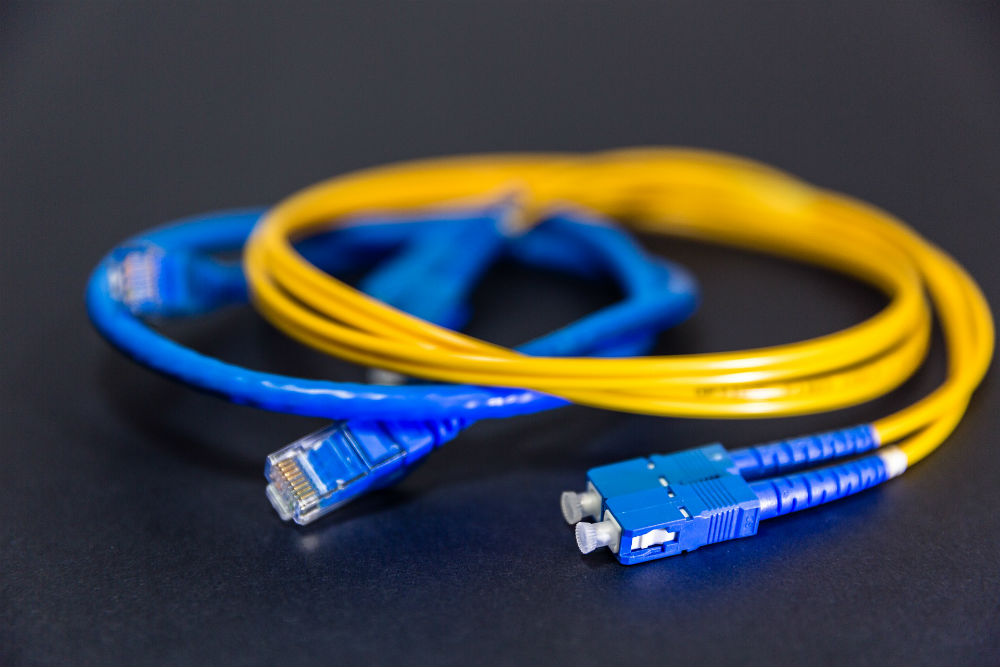

PVC Jackets — PVC which stands for Polyvinyl Chloride, is a generic jacket used for cables that is made of plastic. It is a widely used cable for different applications, such as wiring, communications, computers, and other relevant technological applications. Not to mention, PVC is very flexible and inexpensive. It is also commonly used to designate a specific cable that is not ideal for a cable network application. However, PVC can be a bit risky in case of fire situation. It will release hydrogen chloride and heavy smoke which may put electronic devices and human health to a great threat.

LSZH cable — The abbreviation stands for Low Smoke Zero Halogen, a type of cable made without halogenic materials since these chemicals are toxic to the environment once burned. The “low smoke zero halogen” term refers to a specific cable compound properties. Whilst, the term “zero halogen” refers to the amount of halogens utilized to make such compound.

What’s the Difference Between PVC Jackets and LSZH Cable?

Based on the physical attributes of these two cables, the difference is indeed apparent. The LSZH cable feels coarse and is stiffer because of a compound that is flame-resistant. Whilst PVC is smooth and soft. Moreover, LSZH cables are more appealing in terms of aesthetic compared to PVC jackets. Not only that, the differences between these two can be determined in three components:

- Elasticity – Unlike the compounds found in PVC cables, there is a restricted amount of elasticity compound that LSZH compounds have. Hence, LSZH cables are not recommended for continuous tilt applications.

- High Temperature – In the event a PVC cable is on fire, it gives off toxic chemicals, gases, and acids which are all dangerous to the environment and human beings. Whereas, LSZH cables have a flameproof jacket, meaning they don’t give off such toxic chemicals even if it is burned. These cables can also decrease the level of smoke density.

- Price – In terms of price, PVC cables are somehow cheaper than LSZH cables, however when talking about human health safety, LSZH will always be the ideal choice.

When is the Ideal Time to Use PVC or LSZH?

These cables both have equal feasibility performance when used in modern infrastructures. Hence, it really depends on the scenario when choosing which cable to use. PVC cables have been utilized in creating applications for control and power for tons of years. These cables are used for flat surfaces from wiring systems, or for upright surfaces between floors.

LSZH cables on the other hand, are more suitable for areas where possible fire crisis will happen. Considering the fact that the primary risk in case of fire are the produced smoke and gas. Therefore, it’s crucial that the installed devices and materials contribute less gas and smoke as possible in case fire may arise.

The LSZH cables can be installed in these cases:

- Spaces that are confined with large numbers of cables that are all in close areas.

- Central office equipment and applications for telecommunications.

Deterioration of Cables

One of the main concerns with PVC cables is they may deteriorate when used over time in specific conditions, and one of them is oil. These cables are made of petroleum substance that will start to dissolve if mixed with oil. Since oil and grease are rampant in certain areas especially in the industrial setting. The cables’ lifespan will improve dramatically with jacketed cable that is oil proof like Polyurethane.

UV exposure is another circumstances that might decrease the cable’s lifespan. If cables are installed in direct sunlight for longer periods, replacement is needed more regularly.

Conclusion

Today, regardless if PVC cables are the top choice in the cable industry, the usage has lessened over the past decades. Whilst, LSZH cables are significantly more advanced in terms of features, they are more suitable to certain applications, as mentioned above. Also, when it comes to usage, it mainly depends on your project needs. However, if you are doubtful, it is best to consult with professional cable experts, just like https://www.otscable.com, a professional and leading cable communications network factory.