Artificial skin produced using nanoscale technology could improve wound recovery for patients with burns or skin grafts.

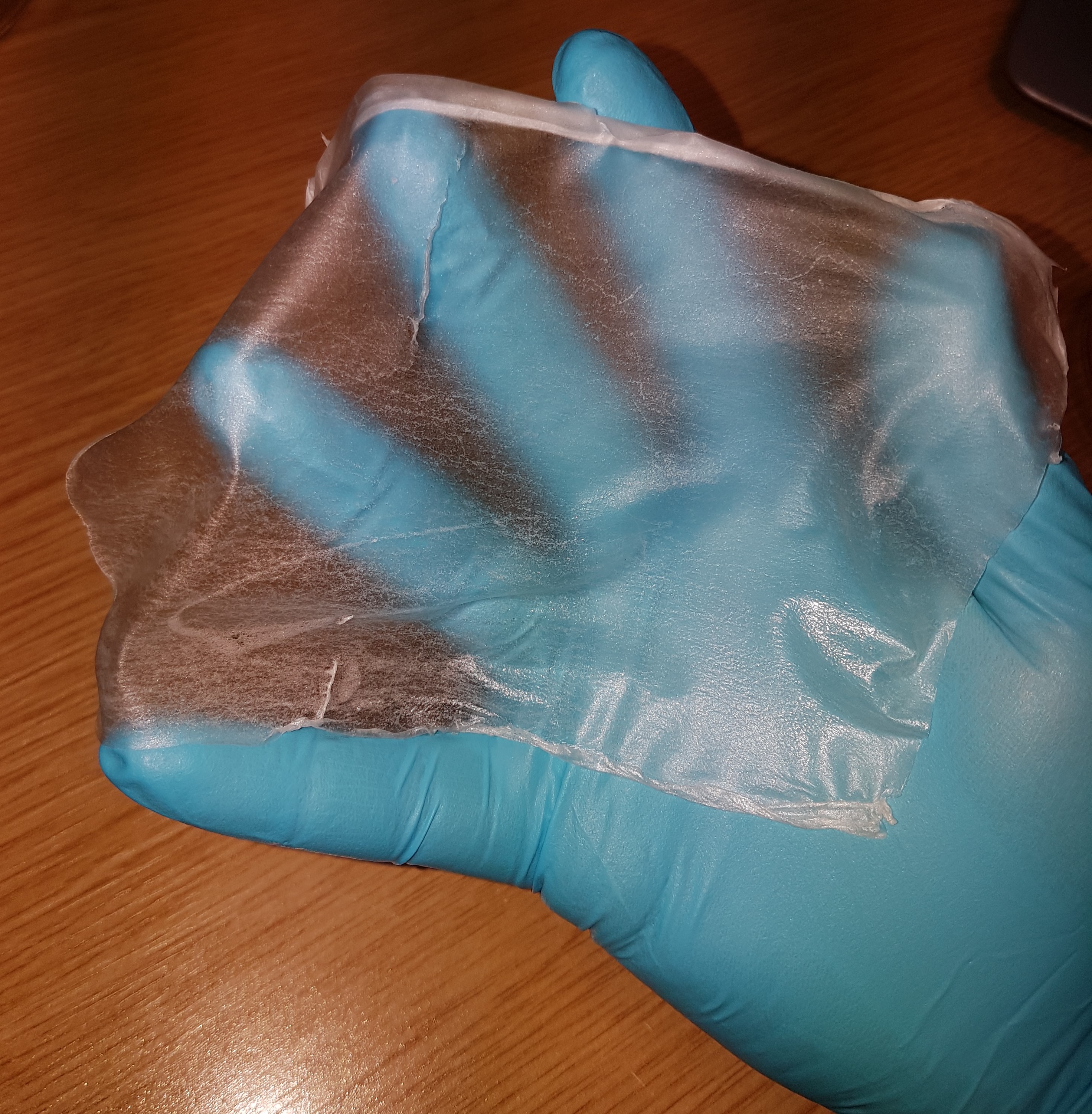

Engineers have devised a fabric dressing whose thickness and elasticity can be custom-matched to specific areas of the body. The material is able to be absorbed by the skin’s own tissue as it heals.

Two synthetic materials are blended to produce nanometre-sized fibres – thousands of times thinner than a hair – which can be fabricated in minutes.

Researchers at the University of Edinburgh produced their custom fabric using a recently developed method, known as nozzle-free electrospinning.

Their device comprises a rotating cylinder above a pool of solution containing the two components of the fabric.

As the cylinder spins under high voltage and temperature, tiny fibres are quickly produced from the liquid and spun onto an adjacent hot surface. As the fibres cool, the fabric is formed.

The component mixture can be altered to produce dressings of varied thicknesses and elasticity. It incorporates a recently discovered material, known as polyglycerol sebacate, which is stretchy and compatible with human tissue.

Tests with skin cells showed that the material’s small scale fibres provide a scaffold on which newly formed skin can grow.

Research will now focus on further developing and testing the material for medical use, which the team expects may take about four years. The study was published in Medical Engineering & Physics.

Dr Norbert Radacsi of the University of Edinburgh’s School of Engineering, who led the study, said: “Our technique is a cost-effective way of making artificial skin adapted for all areas of body, to accelerate the wound healing process.”

Antonios Keirouz of the University of Edinburgh’s School of Engineering, who performed the experiments in the study, said: “Dressings made from this new fabric would be absorbed by the body, reducing the need for frequent changes.”